Laboratorium Pengujian Tekstil Balai Besar Tekstil telah terakreditasi oleh National Association of Testing Authorities (NATA) Australia (sejak tahun 1994) dan Komite Akreditasi Nasional (KAN) Indonesia (sejak tahun 2003). Akreditasi Laboratorium diadakan melalui asesmen audit dan penilaian oleh ahli-ahli professional berdasarkan persyaratan standar internasional yaitu ISO/IEC17025- 2005.

Laboratorium Pengujian Tekstil Balai Besar Tekstil melayani pengujian:

- Serat

- Benang

- Kain

- Tahan Luntur Warna

- Identifikasi Zat Warna

- Analisa Zat Pembantu

- Analisa Air dan Limbah

- Kadar Zat pada Bahan

Metoda pengujian yang digunakan secara garis besar berdasarkan standar SNI, ISO, ASTM, BS, AATCC dan standar lainnya sesuai permintaan pelanggan.

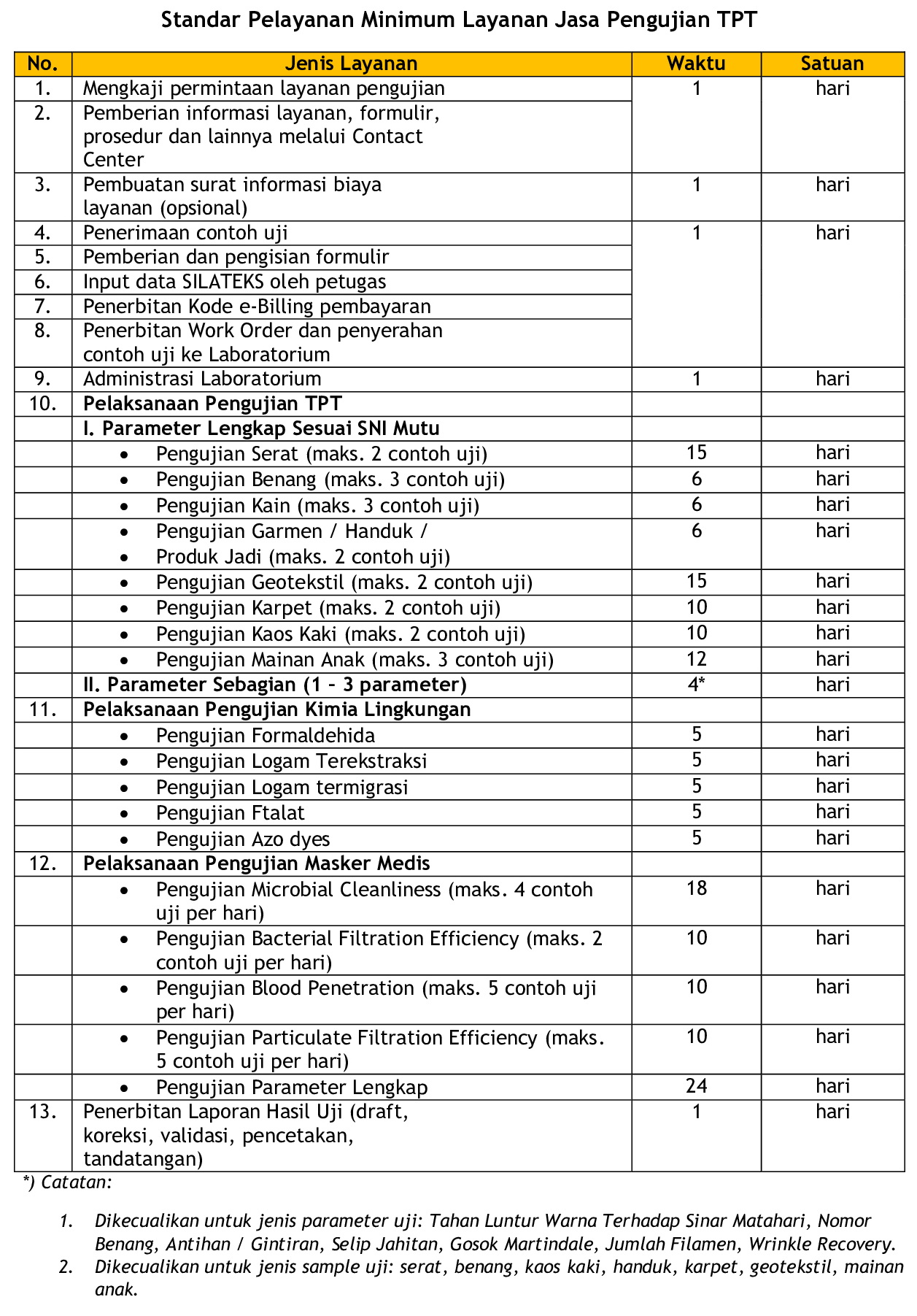

Alur Layanan Jasa Pengujian TPT

- Pelanggan membuat permohonan Layanan Jasa pengujian baik datang langsung maupun melalui e-mail/surat penawaran

- Subkoordinasi Pemasaran membuat surat penawaran Pengujian

- Pelanggan menyerahkan surat persetujuan pengujian dan sampel uji

- Subkoordinasi Kerjasama memeriksa kecukupan sampel uji sesuai persyaratan

- Subkoordinasi Kerjasama mengajukan pemohonan kepada Benda

CHEMICAL TESTING

- Moisture Regain/Moisture Content – SNI 08-0263-1989

- Oil Content – AATCC TM 97:2009

- Fiber Identification – AATCC 20 : 2007, SNI 08-0264-1989

- Fiber Content – SNI ISO 1833-1 s/d 21:2011, SNI ISO 1833-24:2011, IS0 1833-1 s/d 5:2006,IS0 1833-6:2007, ISO 1833-7 s/d 19:2006, IS0 1833-20:2009, IS0 1833-212006, IS0 1833-24:2010, ATCC 20a:2008

- Water Permeability – ISO 12958:2010, SNI 08-6511-2001

- Dimensional Change in Ironing – JIS L 1057:2006

- Vertical Flammability – SNI 08-1512-1989, ASTM D 6413-08

- Flammability-Tablet – SNI 08-7180-2006

- Whiteness – SNI ISO 105-J02:2011, AATCC 110:2005, ISO 105-J02:1997

- Analysis of Textile Resin Finish in Fabric – SNI 08-0459-89

- Free Formaldehyde – JIS L 1041:2011, SNI ISO 14184-2:2010, ISO 14184-2-2011, AATCC 112-2008

- Mercerization – SNI 08-0300-1989, AATCC TM 89-2008

- Flammability for Apparel (45 degree) – SNI 08-0989-2011, ASTM D1230-10

- Absorption (drop method) – SNI 08-0279-1989, AATCC 79-2007

- Spray Test – SNI ISO 4920:2010, AATCC TM 22-2010, ISO 4920:1981

- Absorption (Basket Method) – SNI 08-0404-1989

- pH Value – AATCC 81:2006, ASTM 0216544(2006), SNI 08-4645-1998, ISO 30712005

- Dimensional Change in Laundering – SNI ISO 5077:2011, AATCC 96:2009, AATCC 135:2010, ISO 5077:2007

- Durability Performance – SNI 0296-2009, AATCC 124:2010

- Hydrostatic Pressure – SNI 08-0295-1989, AATCC 127:2008

- Rain Test (Bundesmann) – SNI 08-0278-1989

Color fastness to:

- Acid Spotting – ISO 105-EO5:2010, AATCC 6:2006, SNI ISO 105-E05:2010

- Alkaline Spotting – AATCC 6:2006, SNI ISO 105-E06:2010, ISO 105-E06:2006

- Pool Water – ISO 105-E03:2010, AATCC 162-2002, SNI ISO 105-E03:2010

- Sea Water – AATCC 106:2006, SNI ISO 105-E02:2010, ISO 105-E02:1994

- Chlorine Bleach – SNI 0286:2008, AATCC 188-2010, ISO 105-N01:1993

- Peroxide Bleach – AATCC 101:2009, SNI ISO 105-N02:2010, ISO 105-N02:1993

- Rubbing – SNI 0288:2008, ISO 105-X12:2001 (E), AATCC 8-2007

- Perspiration – SNI ISO 105-E04:2010, AATCC 15-2007, ISO 105-E04:2008

- Sunlight – SNI IS0 105-B01:2010, AATCC 181-2005, ISO 105-B01:1994

- Artificial Light (Xenon) – SNI ISO 105-B02:2010, AATCC 16-2004, ISO 105-B02:1994

- Washing SNI – ISO 105-C06:2010, AATCC TM 61-2009, ISO 105-C10:2006, ISO 105-C06:2010

- Water – AATCC 107-2007, ISO 105-E01:2010, SNI ISO 105-E01:2010

- Sublimation – AATCC 117-2004, ISO 105-P01:1993, SNI ISO 105-P01:2010

- Dry Cleaning – SNI ISO 105-D01:2011, AATCC TM 132-2009, ISO 105-D01:2010

- Hot Pressing – SNI ISO 105-X11:2010, AATCC 133-2009, ISO 105-X11:1994

- Phenolic Yellowing – SNI ISO 105-X18:2011

Dyestuff Identification on:

- Cellulose Fiber – SNI 08-0621-1989

- Polyester Fiber – SNI 08-0519-1989

- Nylon Fiber – SNI 08-0767-1989

- Protein Fiber – SNI 08-0987-1989

- Pore Size – SNI 08-4418-97

- Starch Content – SNI 08-0265-89

- Honeydew Content – SNI 08-0986-1989

- Peroxide,Acid,Alkaline,Oxidator/Reductor Content – Herman Busser

- Indigo Content – Rawson

- Viscosity – Brookfield

Others:

- Recommendation on Care Label – SNI 08-0336-2005

- Recommendation on Fabric Defect

PHYSICAL TESTING

Cotton Fiber

- Staple Length – ASTM D 1447-94, SNI 0800888-1989

- Staple Length Method Fibrograph UR Method, Span Length 50% & 25% – Digital Fibrogram/ASTM D 1447-07e1 and Characteristic of Cotton (HVI) – ASTM D 5867-05

- Fiber Maturity – SNI ISO 4912-2010/ASTM D 1442-06

- Strength (Pressley) – SNI.08-0263-1989/ASTM D1445-07

- Shirley Analyser – SNI.08-1268-1989/ASTM D 2812-07

- Nep Number – Balance

- Moisture Regain – SNI 08-0263-1989/ASTM D 2495-07

- Wax Content – SNI 08-0620-1989/Soklet Extraction

- Honey Dew – SNI 08-0986-1989

- Ash Content – Ash Method

- Strength Elongation (Stelometer) – ASTM D1445-05

Other Fiber

- Staple length (technical of bast fiber) – SNI.08-1113-1989/ASTM 5103-07

- Staple Length (elementary) – BBT Standard

- Fineness of bast fiber – SNI 08-1111-1989, ASTM D1577-07/ASTM D 2495-07

- Staple Length of synthetic fiber – SNI 08-0580-1989

- Denier of synthetic fiber – SNI 08-0589-1989/ASTM D1577

- Crimp: crimp per 25mm, crimp ratio and crimp modulus ratio – ASTM D 3937-07

- Single strand strength of synthetic fiber (standard wet) – SNI 08-0618-1989 /ASTM D 3822-08 (Computerized)

- Moisture Regain – SNI 08.0263-1989 / ASTM D 24954-07

- Melting Point – BBT Standard

- Density – SNI 08-0264-1989

- Oil Content – SNI 08-0620-1989

- Shrinkage in boiling water – SNI.08-2940-92/ASTM D 2259-02

- Shrinkage in oven 210 degree Celcius – SNI.08-2940-92/ASTM D 2259-02

- Diameter of fiber – Microscopic

- Photo of fiber cross section – Microscopic

Fabric

- Width – SNI ISO 22198:2010/ASTM D 3774-96

- Length Measurement (length width) – SNI ISO 22198:2010/ASTM D 3774-96

- Thickness – SNI ISO 5084:2010/ASTM D 1777-96

- Weight/m2 – SNI ISO 3801:2010/ASTM D 3776-M-09a

- Weight per meter – SNI ISO 3801:2010/ASTM D 3776-M-09a

- Total of warp or weft – SNI ISO 7211-2:2010/ASTM D 3775-08

- Number of wales and course – SNI 0458:2010/ASTM DD 3887-08

- Twist of weft or warp yarn – SNI ISO 7211-4:2011/ASTM D1422-99(2008)

- Basic Design – SNI 08-0274-1989

- Single Strand Strength for weft or warp yarn (by Instron or Autograph) – SNI 7650:2010/ASTM D 2256-89 (Instrument/Computerized)

- Fabric Strength (by Instron or Autograph) – SNI 0276-2009/ASTM D 5035-08/ASTM D 5034-09

- Tearing Strength (Elmendorf) – SNI ISO 13937-1-2010/ASTM D1424-09

- Tearing Strength (Tounge Method) – SNI 0521:2008/ASTM D 2261-07a

- Tearing Strength (Trapezoid Method) – SNI.08-1269-1989/ASTM D 5587-08

- Sewing Strength (by Instron or Autograph) – ASTM D 1683-07/ISO 13935-1 and 2

- Bursting Strength of Knitted Fabric – SNI ISO 13928-1:2010/ASTM D 3786-09

- Crease Resistance – SNI ISO 2313:2011/AATCC 66:1998

- Stiffness – SNI 08-0314-1989/ASTM D1388-08

- Abrasion (Martindale) – SNI ISO 12497-1:2010 1 and 4

- Drape – Daisho Drape Tester – SNI 1511-2004

- Pilling (ICI): 3 hours, 5 hours, 10 hours – SNI ISO 12945-1:2013

- Static Electricity (based on wool std/cotton std – JIS L1094-2008

- Browing/Skewness – ASTM D 3882-08, SNI.08-4622-1998

- Rubbing test of pale (Crockmeter-100 rotations) – BBT Manual

- Seam slippage of yam in woven fabric – SNI ISO 13936-1 and 2 ASTM D 1683-077

- Seam Strength – ASTM D 434-95, abolisi

- Air Permeability – JIS L.1979, SNI.08-7648-2010

- Defect of woven fabric/30m – SNI 0277:2013

SPECIAL TESTING